December 6, 2017

We're very excited to announce a new offering: custom matte stickers. This new product in our all-star lineup features a writable surface, a satin-like appearance, durable laminate and free laser die cuts. Yes, lasers.

This new choice of finishing option on our die cut stickers means you can pick between two different styles, matte and glossy. These stickers are great for detailed artwork, or times when you want your custom sticker designs to standout in the crowd. The matte lamination is indoor and outdoor durable, so your brand can travel far and wide for years to come.

We're very excited to announce a new offering: custom matte stickers. This new product in our all-star lineup features a writable surface, a satin-like appearance, durable laminate and free laser die cuts. Yes, lasers.

This new choice of finishing option on our die cut stickers means you can pick between two different styles, matte and glossy. These stickers are great for detailed artwork, or times when you want your custom sticker designs to standout in the crowd. The matte lamination is indoor and outdoor durable, so your brand can travel far and wide for years to come.

Matte stickers versus Glossy stickers

Here's a side by side of our December monthly seasonal sticker sheet in matte (left) and glossy (right) stickers in natural light. You can see the shine of the reds and greens on the glossy and the more muted appearance on the matte sticker. Both are great options, but they have different uses, and certain designs work better on matte than with glossy, namely very detailed artwork and creative presentations. These sticker sheets are fun and utilitarian (they make present labels!), and they offer up a holiday greeting along with a comparison for how these stickers will finish. Read on to see more behind the scenes as matte stickers enter the StickerGiant family. [caption id="attachment_65503" align="alignnone" width="770"] Matte stickers on the left and glossy stickers on the right. Both die cuts, but with a different finish.[/caption]

Matte stickers on the left and glossy stickers on the right. Both die cuts, but with a different finish.[/caption]

Behind the scenes on the laser

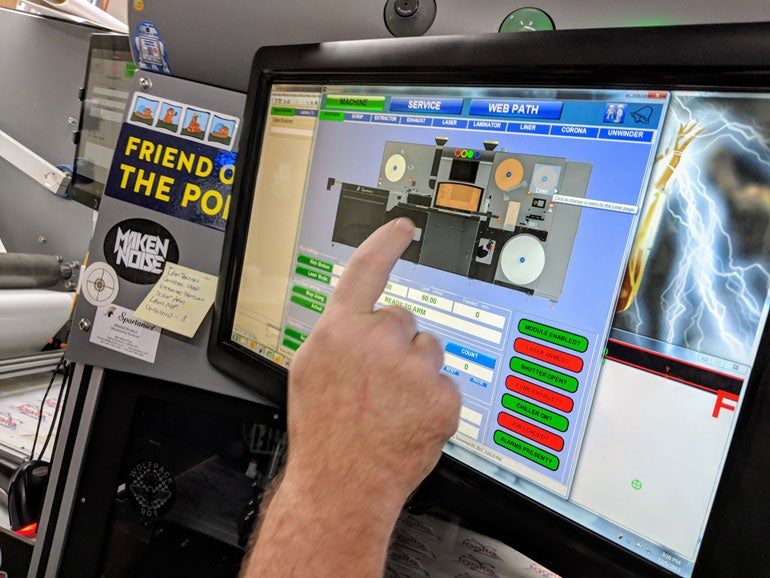

We sat with Nate, one of our laser operators, as he ran one of the first orders of matte stickers to come through the shop. Here's a few photos of the work in process. [caption id="attachment_65463" align="alignnone" width="770"] Laser operator Nate checks the settings on the die cutter.[/caption]

[caption id="attachment_65423" align="alignnone" width="770"]

Laser operator Nate checks the settings on the die cutter.[/caption]

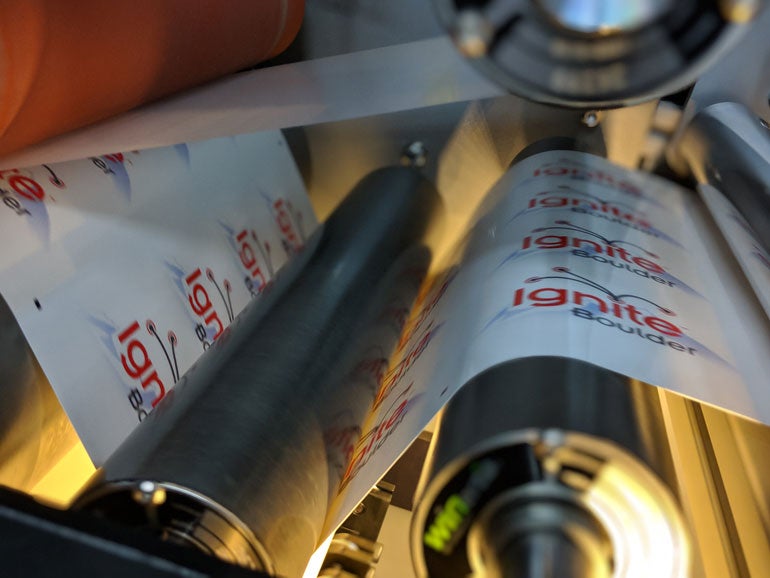

[caption id="attachment_65423" align="alignnone" width="770"] Ignite Boulder matte stickers running through the roller as lamination applies to the substrate.[/caption]

[caption id="attachment_65473" align="alignnone" width="770"]

Ignite Boulder matte stickers running through the roller as lamination applies to the substrate.[/caption]

[caption id="attachment_65473" align="alignnone" width="770"] Laser operator Nate calibrating the laser die machine. You can see a full diagnostic display of the machine from this view.[/caption]

[caption id="attachment_65443" align="alignnone" width="770"]

Laser operator Nate calibrating the laser die machine. You can see a full diagnostic display of the machine from this view.[/caption]

[caption id="attachment_65443" align="alignnone" width="770"] The interior of the rollers as the lamination applies to the substrate. The light on the interior allows for the operators to view the stickers as they process.[/caption]

[caption id="attachment_65433" align="alignnone" width="770"]

The interior of the rollers as the lamination applies to the substrate. The light on the interior allows for the operators to view the stickers as they process.[/caption]

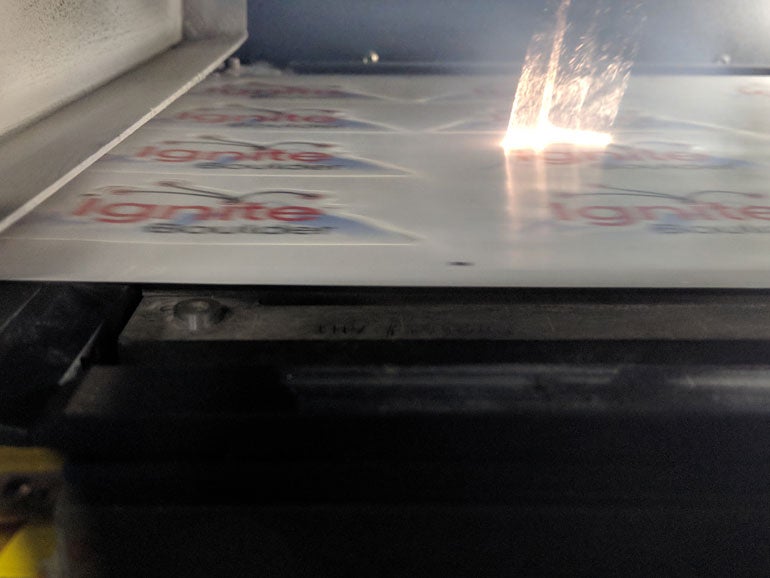

[caption id="attachment_65433" align="alignnone" width="770"] The laser die cutter traces a path then cuts the substrate, while on the left side of the image, a vacuum separates the newly cut stickers from the roll.[/caption]

[caption id="attachment_65453" align="alignnone" width="770"]

The laser die cutter traces a path then cuts the substrate, while on the left side of the image, a vacuum separates the newly cut stickers from the roll.[/caption]

[caption id="attachment_65453" align="alignnone" width="770"] As the stickers leave the laser area of the machine, they enter this final section where they all lay out on a conveyor belt that stacks them neatly for counting and prepping for QC and then shipping.[/caption]

[caption id="attachment_65483" align="alignnone" width="770"]

As the stickers leave the laser area of the machine, they enter this final section where they all lay out on a conveyor belt that stacks them neatly for counting and prepping for QC and then shipping.[/caption]

[caption id="attachment_65483" align="alignnone" width="770"] Just a little view from Nate's perspective as he operates the laser die cutter to close out this look into the world of matte stickers.[/caption]

Just a little view from Nate's perspective as he operates the laser die cutter to close out this look into the world of matte stickers.[/caption]